As an essential component of aerosol cans, aerosol valves play a crucial role in the functionality and performance of these products. Whether you are a manufacturer looking to source aerosol valves or a consumer interested in understanding more about these intricate devices, this comprehensive guide will provide you with professional insights and authoritative information to help you make informed decisions.

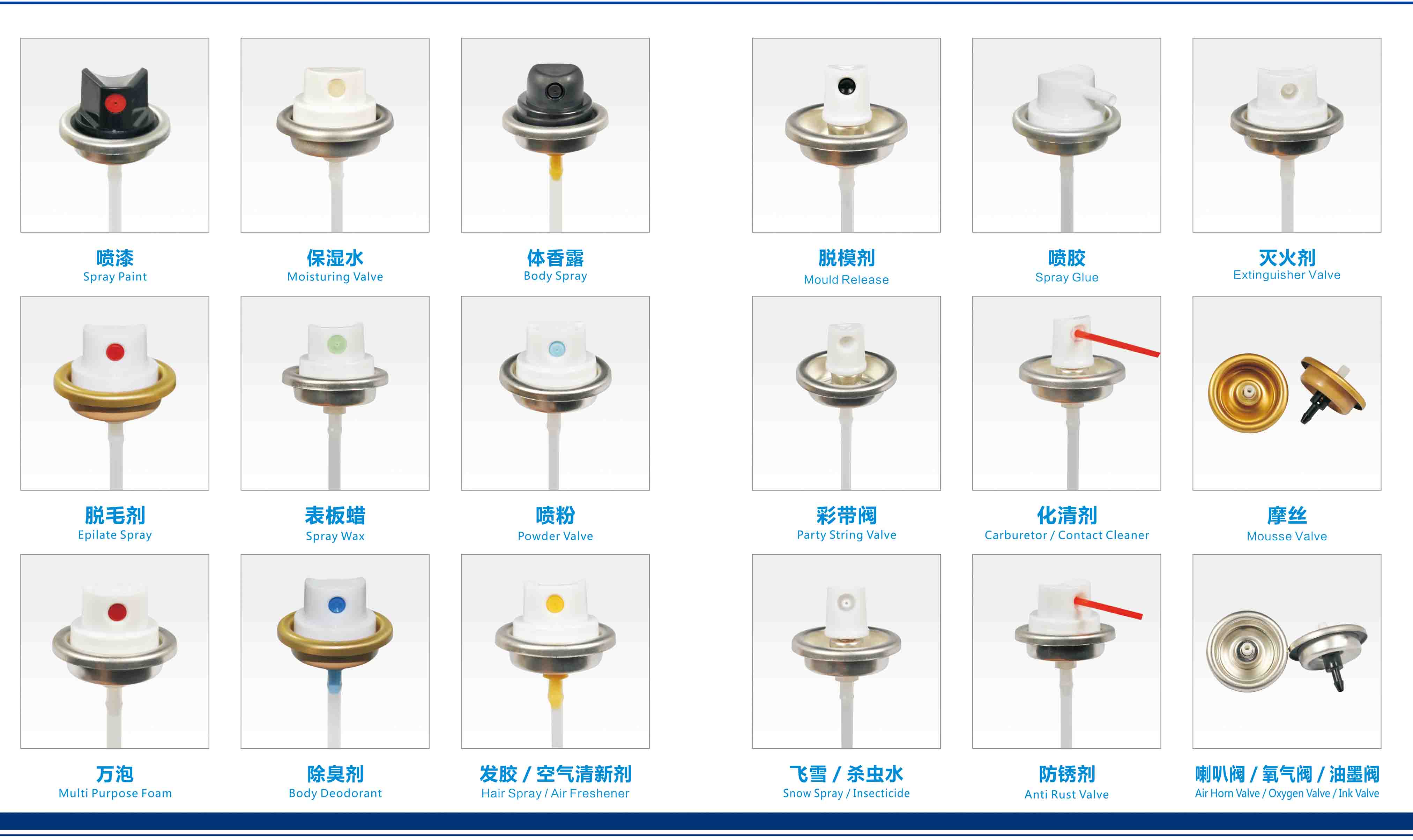

Firstly, let's delve into the fundamentals. Aerosol valves are responsible for dispensing the propellant and product from aerosol cans. They control the flow, spray pattern, and dosage, ensuring efficient and precise application. Common types of aerosol valves include metered valves, continuous valves, metered-dose valves, and non-metered valves.

Factors to Consider when Choosing Aerosol Valves:

a. Valve Compatibility: Different aerosol valves are designed to work with specific can sizes and diameters. Ensure compatibility between the aerosol valve and the can to achieve optimal performance and fit.

b. Spray Characteristics: Consider the desired spray pattern, such as mist, foam, stream, or spray cone. Depending on the application, certain valves offer adjustable spray patterns to suit various needs.

c. Actuator Options: Evaluate the actuator designs available, including buttons, caps, and stems. Consider factors such as ergonomics, ease of use, and the intended application when selecting an appropriate actuator.

d. Propellant Compatibility: Ensure that the aerosol valve is compatible with the specific propellant and formulation used in your product. This will guarantee optimal performance and prevent any compatibility issues.

e. Quality and Safety Standards: Look for aerosol valves that meet industry standards and certifications, ensuring product integrity, safety, and reliability. Consider the valve's materials, construction, and testing processes.

Choosing a Reliable Aerosol Valve Supplier:

a. Industry Experience: Select a supplier with substantial experience in manufacturing aerosol valves. A reputable supplier with a proven track record will provide comprehensive expertise and reliable products.

b. Customization Options: If you require customized aerosol valves for your specific application, choose a supplier that offers OEM (Original Equipment Manufacturer) or ODM (Original Design Manufacturer) services. This allows for tailored solutions to meet your specific requirements.

c. Quality Assurance: Ensure that the supplier implements strict quality control measures throughout the manufacturing process. Request information about their quality management system, inspection procedures, and testing standards.

d. Customer Support: Look for a supplier that offers excellent pre-sale and after-sales support. This includes prompt communication, technical assistance, and the ability to address any concerns or issues that may arise during the purchasing process.

Requesting Samples:

Before making a bulk purchase, it is advisable to request samples from potential suppliers. Testing the aerosol valves firsthand will allow you to evaluate their performance, quality, and compatibility with your product. Reputable suppliers often provide free samples for testing purposes.

Conclusion:

Choosing the right aerosol valve is vital to ensure the optimal performance and functionality of your aerosol products. By considering factors such as valve compatibility, spray characteristics, actuator options, propellant compatibility, and quality standards, you can make well-informed decisions. Additionally, working with a reliable and experienced aerosol valve supplier that offers customization options and excellent customer support will contribute to your overall satisfaction. Don't hesitate to request samples to ensure a perfect match for your requirements. Now you have the knowledge and tools to confidently choose and purchase aerosol valves that meet your specific needs.